Building a universal QSPI flash controller

|

Flash is an important component in any FPGA design, and a vital component in any soft-core CPU design. First, many FPGAs load their configurations on power up from flash. Thus, if you want your configuration to load from non-volatile memory and without using the JTAG, placing your design into the flash memory is often a requirement. The good news is that this means most FPGA development boards already include a flash memory for configuration. The even better news is that flash chips are cheap enough that there’s usually plenty of space available for user applications in addition to the configuration memory.

Just think through those possibilities: what would you do in your design if you had non-volatile memory available to you? Even better, what if you had 8-16MB of non-volatile memory available?

Now, before you get too excited, be aware: there’s usually a beginner out there

who thinks that flash can be treated

like normal memory. No, I’m sorry, it can’t. While you can read from

flash fairly quickly, writing to

flash is more problematic. If you want

to change something in flash, you have

the choice of erasing the flash–that

is to turn bits to ones and hence the bytes to 8'hff, and then programming the

flash,

also known as turning bits to zeros. Of these two, the erase is the most

problematic. Depending on the flash,

you might only be able to erase 64kB blocks at a time. (Yes, some

flash chips allow 2kB sub-sector erase

operations.) Worse, a sector erase command will take anywhere between a half

second and two seconds. It is slow.

For these reasons, flash memory make a good ROM addition to your design.

As I’ve written before, I’ve now created several flash designs in support of my own ZipCPU development.

Today’s story, though, starts with the Arty board, now sold by Digilent under the name Arty A7. This is a wonderful starter board for anyone who wants to try building their own embedded CPU: it has a decent sized FPGA, DDR3 SDRAM, a 100Mbps ethernet port, a couple of switches, buttons, LEDs, some color LEDs, four PMod ports and … 16MB of flash memory.

When I first built my own design for the Arty, Digilent shipped it with a flash chip built by Micron. Sadly, my original flash controller couldn’t handle this Micron flash device. Why? Because for a common standard such as Quad-SPI (QSPI), the Spansion and Micron chips were just too different for my controller. Well, that and I originally wanted to build a 200MHz design, but that’s a different story for a different day.

Micron’s flash implementation had the problem that it was difficult to reset. There were modes the flash could get into where, if you reloaded your FPGA design, the flash might no longer respond the way you thought it should. Worse, Micron’s design offered settings under which the flash might power up into a state unknown to the design. These extra modes were “features”, designed to help you achieve high speed operation immediately on start up. To me, however, they were liabilities, since it became that much harder to know if my controller would work. I complained about this, and sometime later Digilent modified the board to use a different flash chip.

Of course, this only happened after I finally had a design that worked with the Micron flash device.

Worse, I only discovered that Digilent had swapped flash chips when someone tried to use my OpenArty design, only to discover the new flash was incompatible with the old controller.

It was now time to build a new flash controller. Again. The question before me, though, was whether it might be possible to build a single Quad-SPI controller that I could re-use with any flash device I came across.

This blog article is about the design and verification of that new Quad-SPI flash controller.

Requirements

No, I do not believe in top-down, requirements driven development. As we discussed in the last article, this flash controller is not the first flash controller I’ve ever built. Reality seems to dictate that spiral development, or other iterative development approaches work better. Indeed, I’m slowly becoming a believer in incremental design approaches.

Still, it makes sense to start the story off with a discussion of what a “better” flash controller would look like. What should it do, and what functions should it support?

First and foremost, any flash controller must be able to read from the flash memory. This is the basic requirement, without which we will fail.

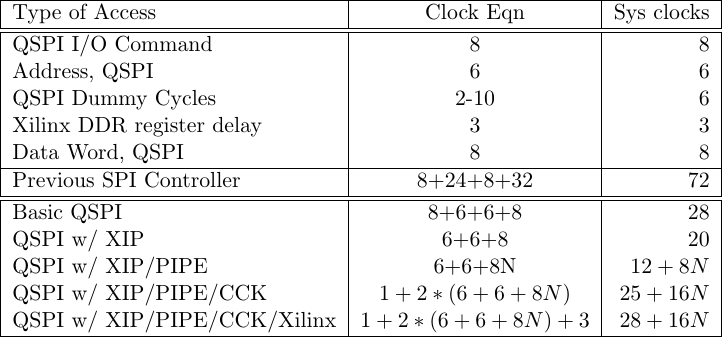

When we last built a SPI flash controller, it could read one word every 64 (8+24+32) clock cycles, as shown in Fig. 2 below.

|

On the other hand, if you want to build a flash controller that stands out when compared to other controllers, a one-size-fits most controller, or even, as I’ve started to call this, a Universal QSPI flash controller, then you need to do more than just read values from the flash: you need to read them fast. How fast? As fast as the device will support a read using logic synchronous to the rest of the design.

This will force us not only into the

Quad-SPI

flash territory, where four

data lines are strapped together, but it’s also going to have us looking

at whether or not we can keep the

QSPI

clock running at the same

rate as the system clock rate. For my OpenArty design, this means I am going

want to run my

QSPI

flash at a 100MHz clock rate–twice as fast as most

QSPI

flash

controllers. Since most

QSPI

flash devices support 108Mhz, I figured I should be good here. Hence,

this was my second criteria: running the in

QSPI

mode, with the

QSPI

SCK line

running at the system clock rate.

|

This gets us down to 28 (8+6+6+8) SCK clock cycles per read.

If you are working to achieve speed, however, this still isn’t fast enough.

Most flash devices offer a mode where, after one flash command you can leave the flash in some sort of eXecute-In-Place (XIP) mode. In this mode, the next flash command starts immediately by sending a 24-bit address, then after some amount of wait, you can read your data. This will save us 8 flash clock cycles by not needing to send a new flash read command.

|

We’re now at 20 (6+6+8) SCK cycles per read.

This still isn’t fast enough for me: I wanted to build a flash controller that can handle burst reads.

By “burst reads”, I mean I wanted my flash controller to be able to read multiple words in the same transaction. The first word will require sending an address and several dummy cycles, before using up eight clocks for the data. If we want to keep reading, we can then arrange for the second and subsequent words to take no more than 8 SPI additional clocks each.

|

This brings us to 12+8N (6+6+8N) SCK cycles per N reads,

asymptoting at 8-cycles per read.

Now that’s a fast QSPI flash controller!

Yes, there is a faster mode supported by some flash chips where the flash chip returns its data on both edges of the clock. We’ll save the investigation of those chips and that mode for a later time.

But what about programming the flash? Sure, I could use the vendor tools to program my flash, but … I like to have as much control over my design as I can get. Therefore, I want an option whereby I can erase and program my flash device via my own controller.

|

In addition, modern Flash devices support many features beyond just erasing and programming their memory region. Many of them also support an identification code, whereby you can determine the make and size of your device. They might also support “One-Time-Programmable” memory regions–allowing designers to place special, often build-specific cryptographic data into the devices they then send to customers.

Supporting all of these features would be nice, but only if they didn’t cumber the basic read capability of the controller. So let’s make this capability an option, and then work to make it a cheap option that doesn’t expand our controller by all that much.

As we’ll see later, the read-manufacturer ID command support didn’t turn out to be an optional feature. Indeed, I needed to use it to get the design working in the first place–but more on that when we get there.

Ok, how have we done? Have we finally specified the perfect QSPI flash controller? Is this finally everything we need from a QSPI flash controller?

I thought so at first. So, after building it, I was quite pleased with my work.

Then my requirements started falling apart.

Most Xilinx designs, you see, require that the

Xilinx startup sequence be able

to control the flash I/O pins

independent of the design. The unfortunate result is that you can only access

the SCK

(QSPI

serial clock) pin through a special STARTUPE2

primitive.

Should you need to use this primitive, you’ll lose your access to the ODDR

primitive

necessary to control the clock.

The Arty

is an unusual development board, in a good way, because it doesn’t have this

problem. Digilent created a second I/O pin

which they also tied to the SCK

pin.

Hence, we can still get system clock rate I/O (100MHz) from our flash

controller.

My Nexys Video board

wasn’t so lucky. Neither was my

Basys3 board.

Both of these boards require that CCK line (configuration clock) going to the

flash SCK pin must go through the

STARTUPE2 primitive.

Hence, these design will need to use a 50MHz SCK.

Strangely, that wasn’t my first problem.

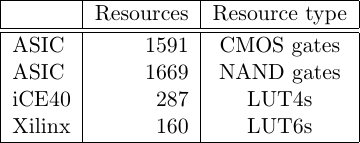

The first problem I realized in my brand new, awesome flash controller design was when someone contacted me to see if they could use my older flash controller in an ASIC project.

ASICs!!?! That changes things a lot! ASICs tend to run at higher clock rates, whereas most flash devices max out at around 108MHz. Worse, an ASIC chip may (or may not) have an ODDR I/O controller in the first place. To even dream of ASIC device support, I really needed an arbitrary clock divider.

Since I don’t normally build ASIC designs, I’ll be up front: this new design doesn’t (officially) support ASICs, although I think it could easily be modified to do so. In particular, I’ve discovered several flash devices have different numbers of “dummy” cycles. Were I to rebuild this design for an ASIC part, I’d want to support a varying number of dummy cycles. I might also want to support a run-time adjustable QSPI clock speed.

|

Still, I added a parameterizable clock divider to my “universal” controller. If nothing else, this would solve the problem with my Nexys Video and Basys3 boards.

That wasn’t my last problem either.

As it turns out, if you want to operate using DDR I/O modes, you may need to register your outputs and then your inputs for better performance. This places a delay between when the logic is valid within your design, and a later time when the value comes back from the pin. This delay is non-zero. On a Xilinx chip, there’s a rough 3-clock delay. (I’m still investigating whether or not I can drop it two 2-clocks.) Intel chips can do this with a 2-clock delay. In other words, the delay needs to be parameterizable.

|

|

This was when I started wondering if my requirements had diverged so much that I was now building a “FrankenIP”. Nevertheless, I pressed on, being certain that somewhere, within this Universal IP core that there was a QSPI flash controller trying to break free.

Did I mention that, on top of all these other requirements I wanted a controller

that only had a minimum amount of logic? This is going to dictate, below,

that all of these options we are working with will need to be created using

parameters and generate blocks, but that’s still easy enough to handle.

The difficult part is going to be verifying that all of these various configurations work, while only having the hardware to test a couple of them.

Before leaving this section, let’s summarize our choices in terms of latency and throughput in Fig. 10 below.

|

The top of this chart shows the number of clocks required for each part of a QSPI interaction. The basic transaction costs 8 clocks for the command word, followed by another 6 clocks to send 24-bits of address 4-bits at a time. After this point, the flash chip might require between 1 and 10 “dummy cycles”. This is an annoying requirement necessary to support Micron flash chips. Winbond and Spansion flash chips have a fixed number of dummy cycles: six–so we’ll use that going forward for our calculations. Following the dummy cycles, it takes 8 clocks to transfer one 32-bit word of information.

These are the numbers we’re dealing with.

Now for the controller options. Our last controller, operating in

SPI mode

alone, took 64 clock cycles to transfer a word. Switching to

Quad-SPI

alone brings us down to 28 cycles. Using the eXecute In Place mode allows

us to then skip the eight clocks of the

QSPI

I/O command, bringing our access time down another 8 cycles to 20 cycles. The

next request, however, will require another 20 cycles. On the other hand, if

we can string multiple requests for sequential addresses together into the

same request, using the pipelined mode of the

bus,

we can drop our access time from 20N clocks for N values down to 12+8N

clock cycles.

This is about as fast as a QSPI controller will get.

If you have to use the CCK port of a Xilinx

FPGA,

you’re clock rate will be

slowed down by at least 2x. I placed another clock in the chart above, to

allow the SCK to go low after the CS_n line becomes active. Then, if you are

using the registered Xilinx

DDR primitives,

you’ll be required to slow down another three clocks.

The “Universal” QSPI flash

core

can therefore provide performance somewhere between

12+8N clocks and 28+16N clocks per word, depending upon how it is set up,

how your board is designed, and the

flash

chip on that board.

Timing control loop

Let’s start out with our timing control, because the timing control signals are going to be pervasive throughout the rest of the core.

|

In our highest speed configuration, we’re going to want to handle an SCK

signal equal to our controllers clock rate. Such a signal might generate

an output looking like Fig. 11 on the right. In this figure, the w_qspi_sck

control signal is being used to control the final o_qspi_sck output. (I’ll

also confess, these are top-level signal names. Within

the core,

I’ve used o_qspi_sck to reflect the signal shown at the right labeled

w_qspi_sck. In the non-ODDR modes, there’s no difference between these

two signals, only in the ODDR mode.)

Of course, we’ll want to be able to slow this clock down as well, so let’s create several signals from a basic clock divider circuit that we can use to control our logic below in the presence of a slower clock. These extra signals are shown in Fig. 12 below.

|

The CS_n and SCK signals are part of the basic

QSPI

protocol. If CS_n

is inactive (high), then the other

SPI

signals, primarily clock and data, are allowed to be anything so that they

can be multiplexed together in order to control several chips. The SCK

signal controls the basic data transfer, and so we’ll focus on making sure

the SPI

data values only ever change when SCK falls.

The other clock control signals are:

-

ckstb: True when it’s time to move to the next set of output values.In a DDR output mode, this will be true on every cycle during a transaction. If we are dividing the clock by two, this will be true every other cycle.

-

ckneg: True when it’s time to set theSCKsignal lowSince we’ll only set

SCKlow at the beginning of a cycle, this signal is just a pseudonym for theckstbsignal above. -

ckpos: True when it’s time to set theSCKsignal highThis will take place mid-cycle.

Of course, if we are in a DDR output mode, that is with

SCKtoggling at the system clock rate, then this doesn’t nearly have as much meaning, so we’ll leave it high. -

ckpre: Some of the logic below will require an extra clock cycle to prepare for the next transition. This is the purpose ofckpre. It is designed so as to be true on the clock cycle prior tockstb.

The code within this section is parameterized by several pieces. The first is

the clock division parameter, OPT_CLKDIV. We’ll use this to control a clock

divider in a moment. The second parameter, really a localparam, is the

OPT_DDR parameter. We’ll set this any time OPT_CLKDIV == 0, and use

it to indicate that we are driving the SCK line at our full system clock rate,

using an ODDR output primitive.

localparam [0:0] OPT_ODDR = (OPT_CLKDIV == 0);In the case where OPT_ODDR is true, there’s only ever one clock per

SCK cycle. Hence, we’ll set all of these values true on every clock cycle.

generate if (OPT_ODDR)

begin

always @(*)

begin

ckstb = 1'b1;

ckpos = 1'b1;

ckneg = 1'b1;

ckpre = 1'b1;

endIf we are dividing our clock by two, such as in order to use a CCK port

through a STARTUPE2 primitive,

then we’ll set OPT_CLKDIV to 1. We’ll also need to toggle these

signals–but only while the port is active. That way we can respond

to a request no matter what phase of the counter we are in.

end else if (OPT_CLKDIV == 1)

begin : CKSTB_ONE

reg clk_counter;

initial clk_counter = 1'b1;

always @(posedge i_clk)

if (i_reset)

clk_counter <= 1'b1;

else if (clk_counter != 0)

clk_counter <= 1'b0;

else if (bus_request)

clk_counter <= (pipe_req);

else if ((maintenance)||(!o_qspi_cs_n && o_wb_stall))

clk_counter <= 1'b1;

always @(*)

begin

ckpre = (clk_counter == 1);

ckstb = (clk_counter == 0);

ckpos = (clk_counter == 1);

ckneg = (clk_counter == 0);

endFor the sake of brevity, I’m going to skip the discussion of what it takes to divide the clock down slower then a factor of two. Fig. 12 above should show you what these signals need to look like in that case.

Before leaving this section, I’d like to draw your attention to the presence

of the three generate blocks for this timing: one for OPT_ODDR when the clock

divider is set to zero, one for when the clock divisions is set to one, and one

more for all other cases. That means that, when we get to

formally verifying

this core,

we’ll have to make certain that our formal

verification

work gets applied to each of these three blocks separately.

Reading a word

Now that we have the clock divider out of the way, we can turn our attention to the fun part: building the actual flash controller logic.

If you ever find yourself needing to build your own controller, whether it be a SPI, flash, SDRAM or whatever protocol, the way to do it is usually straight forward: Find the specification sheet for the device you wish to interact with, search through the sheet for the timing diagram illustrating the interaction or interactions you wish to implement, and then build a state machine whose trace matches that diagram.

Building a flash controller is no different.

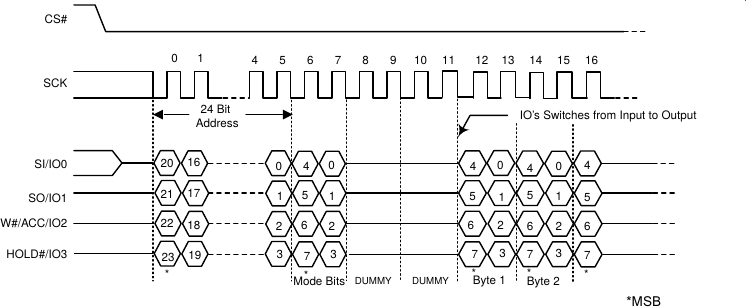

In this case, we’ll be implementing the QUAD I/O READ function. If you look this function up in the data sheet for your device, you’ll find two sets of protocols. The first describes how to get into the QUAD I/O XIP mode. The second I/O function shows a timing diagram describing the QUAD I/O XIP mode we’ll be using.

For example, here’s what the timing diagram looks like for a Spansion device.

|

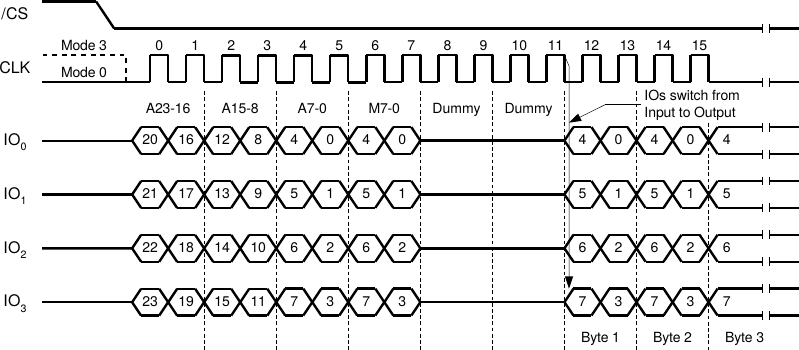

Here’s another one describing how our operation needs to work for a Winbond device.

|

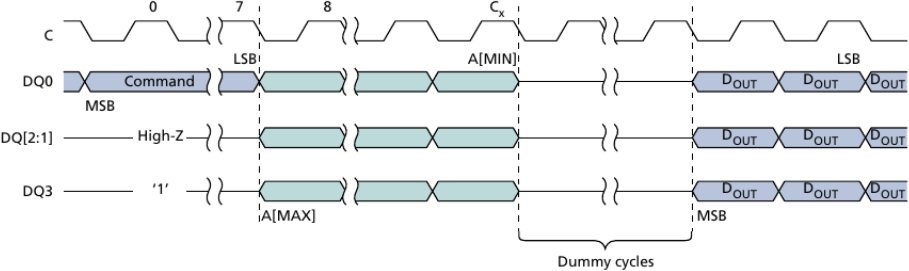

The data sheet for the Micron flash that I have doesn’t show the Quad I/O read from XIP mode, but it does show the Quad I/O read starting with the 8-bit command.

|

We’ll need to use this mode to get into the XIP mode, but more on that in a bit. For now, let’s just assume we are in the XIP mode where we can start immediately by sending the address to the flash device.

In all cases, we’ll need to go through several steps, and we’ll need to

control the chip select (negative logic), o_qspi_cs_n, the

SPI clock signal

sometimes called SCK, o_qspi_sck, and the four outgoing data wires,

o_qspi_dat. Since these wires will eventually be bi-directional at the top

level, we’ll use a third signal, o_qspi_mod, to control the final I/O driver.

We’ll also need to read the data lines from the

device, i_qspi_dat, once it starts returning information to us.

That means that we’ll need to support 3-I/O modes using o_qspi_mod:

-

NORMAL_SPI = 2'b00:DAT[0]is an output,DAT[1]is an input, andDAT[3:2]are both set high. -

QUAD_WRITE = 2'b10: All data wires,DAT[3:0], are outputs of our FPGA. -

QUAD_READ = 2'b11: All data wires,DAT[3:0], are inputs into our FPGA.

localparam [1:0] NORMAL_SPI = 2'b00;

localparam [1:0] QUAD_WRITE = 2'b10;

localparam [1:0] QUAD_READ = 2'b11;How the design interacts with the devices I/O controllers is typically beyond the scope of any of my QSPI flash designs, although it is required to actually implement them within any hardware. At one time, I would specify specific I/O connections in the toplevel:

assign io_qspi_dat[0] = (w_qspi_mod[0]) ? w_qspi_dat[0] : 1'bz;

assign io_qspi_dat[1] = (w_qspi_mod==2'b10) ? w_qspi_dat[1] : 1'bz;

assign io_qspi_dat[3:2] = (w_qspi_mod == 2'b11) ? 1'bz

: (w_qspi_mod == 2'b10) ? w_qspi_dat[3:2]

: 2'b11;I’ve stopped setting my I/O pins in this manner, however.

The primary reason for this is that Arachne-PNR would never guarantee that the placement of this final piece of combinatorial logic would be anywhere near the pin. As a result, I’ve now counseled several individuals who have declared Yosys broken when their design gets sufficiently large that the I/O logic no longer gets placed adjacent to their pins.

While I’m told that this is fixed in

NextPNR, I haven’t (yet) taken the time

to go back and verify this. Instead, I’ve gotten used to configuring the

vendor specific I/O buffers to handle this. Further, since I’m already using

one for the ODDR SCK pin, it makes sense to use the same thing for all of the

pins–if for no other reason than to keep the timing matching throughout the

design.

Hence our design will need to control o_qspi_cs_n, o_qspi_sck,

and o_qspi_dat[3:0]. We’ll also control an intermediate value, o_qspi_mod

to tell an external I/O controller how we want the I/O handled. Similarly,

we’ll be reading from i_qspi_dat[3:0], the data lines that come from that

external I/O controller.

So let’s go back to how this controller will need to control these various wires.

The basic logic is that upon any bus request, we will need to work our way through a sequence of steps.

Just like with the state machine examples in my tutorial, I often find that using a counter to control the steps in the timing diagram feels the most natural–especially in a particularly long sequence such as this one. In this case, the counter idles at zero, and starts counting down immediately following a bus request. Once the counter reaches zero, the interface will return to idle and we should be producing our Wishbone (WB) acknowledgment.

You can see this counter, clk_ctr, and how it relates to our design in Fig. 16

below.

|

This one counter controls everything, so let’s walk through the steps of how it works.

Our logic starts with a bus request,

assign bus_request = (i_wb_stb)&&(!o_wb_stall)&&(!i_wb_we);where we set our counter to 14 plus the number of dummy cycles,

NDUMMY. This number of dummy cycles also includes two cycles for

the mode bits, 8'ha.

initial clk_ctr = 0;

always @(posedge i_clk)

if (i_reset)

clk_ctr <= 0;

else if (bus_request)

clk_ctr <= 5'd14 + NDUMMY + (OPT_ODDR ? 0:1);Note, above, that if we are not running in OPT_ODDR mode, that mode that

runs the SCK at the system clock speed, then we take an extra step to lower

the clock line after activating the chip select. This will cost us one extra

clock, and so this first value of clk_ctr depends upon OPT_ODDR in addition

to NDUMMY.

|

|

On the other hand, if we are running in ODDR mode, then it feels like a waste

to spend a whole cycle to lower SCK, so both CS_n and SCK will drop

together, as shown in Fig. 18 on the right.

Once set, then on any following step during this operation, we’ll decrement our counter until it reaches zero.

else if ((ckstb)&&(|clk_ctr))

clk_ctr <= clk_ctr - 1'b1;Once it reaches zero, we are idle.

Now that we have this counter, we can hang all of the rest of our logic upon it.

For example, here’s the outgoing chip select bit. Remember, this is an active low bit. On any bus request, we’ll clear this bit.

initial o_qspi_cs_n = 1'b1;

always @(posedge i_clk)

if (i_reset)

o_qspi_cs_n <= 1'b1;

else if (bus_request)

o_qspi_cs_n <= 1'b0;Then at the end of every clock interval, we’ll check the clk_ctr to

know if this operation is over. Once the counter gets to one, we’ll set

o_qspi_cs_n again to indicate the end of the operation on the next cycle.

else if (ckstb)

o_qspi_cs_n <= (clk_ctr <= 1);The SPI

clock is a bit more difficult, particularly because of our requirements

creep. If we are running in OPT_ODDR mode, where the outgoing SCK is

determined by an ODDR I/O primitive, then we’ll output a 1'b1 anytime

we want the clock to toggle.

initial o_qspi_sck = (!OPT_ODDR);

always @(posedge i_clk)

if (i_reset)

o_qspi_sck <= (!OPT_ODDR);

else if (bus_request)

o_qspi_sck <= 1'b1;

else if (OPT_ODDR)

begin

if (clk_ctr[4:0] > 5'd1)

o_qspi_sck <= 1'b1;

else

o_qspi_sck <= 1'b0;If you look closely, you might argue that this o_qspi_sck signal is

identical to the o_qspi_cs_n signal. At this most basic mode, and only if

OPT_ODDR is true, then these two signals could share the same logic.

I should point out that I ended up using parameters quite extensively in this

core. OPT_ODDR isn’t the only one. I did this for reasons of code

optimization. By using OPT_ODDR, the synthesis tool can quickly recognize

the if (OPT_ODDR) statement, and that the else following will never get

used. Hence, the synthesis tool will remove the rest of this nested if.

Similarly, if OPT_ODDR isn’t true, this part of the if will get removed

and not count against the logic used by this core.

If OPT_ODDR isn’t true then things get just a little more interesting.

As per the SPI protocol we are following, the clock idles at 1'b1 over the

wire, and so it idles at 1'b1 in non-ODDR mode where we

are directly controlling the over-the-wire interface. On the other hand, if

we are running in OPT_ODDR mode, we are only controlling whether the clock

toggles. Hence in OPT_ODDR mode, the clock pin idles at 1'b0.

(See Figs. 11 and 12 for clarification)

Now, if the clock is low, and ckpos tells us that it is time to raise it,

then set it high. This will occur in the middle of our

state machine

interval, and only if OPT_ODDR isn’t set.

end else if ((ckpos)&&(!o_qspi_sck))

begin

o_qspi_sck <= 1'b1;Finally, if our clock divider tells us it is time to lower the clock, that

is if ckneg is true, then lower the o_qspi_sck output–but only if our

SPI cycle isn’t finished. Notice the check here, as above, for whether are or

are not still within any I/O operation.

end else if ((ckneg)&&(o_qspi_sck)) begin

if (clk_ctr[4:0] > 5'd1)

o_qspi_sck <= 1'b0;

else

o_qspi_sck <= 1'b1;

endNow that we’ve set the chip select and the clock, we can turn our attention

to the data bits. These get set on any bus request, and

then shifted at the end of every clock interval. Ideally, that would mean

we’d set this anytime i_wb_stb && !o_wb_stall. However, I’ve become somewhat

of a stickler for low-logic solutions, and the reality is that these bits are

don’t cares if !i_wb_stb && !o_wb_stall, so I just check for !o_wb_stall

here.

initial data_pipe = 0;

always @(posedge i_clk)

if (!o_wb_stall)

begin

// Set the high bits to zero initially

data_pipe <= 0;

data_pipe[8+LGFLASHSZ-1:0] <= {

i_wb_addr, 2'b00, 4'ha, 4'h0 };

end else if (ckstb)

data_pipe <= { data_pipe[(32+4*((OPT_ODDR ? 0:1)-1))-1:0], 4'h0 };

assign o_qspi_dat = data_pipe[28+4*(OPT_ODDR ? 0:1) +: 4];Perhaps if I were interested in building a lower power design, I’d want to eliminate any extraneously toggling data.

initial data_pipe = 0;

always @(posedge i_clk)

if (!o_wb_stall)

begin

data_pipe <= 0;

if (i_wb_stb)

data_pipe[8+LGFLASHSZ-1:0] <= {

i_wb_addr, 2'b00, 4'ha, 4'h0 };

// ...But low-power isn’t my current goal.

For now, you can see how LGFLASHSZ address bits get set, the lower two

address bits get cleared (since we are responding to a 32-bit data

bus request), and the 4'ha

mode bits get set. These mode bits will help to guarantee that we don’t leave

XIP mode once we’ve gotten into it.

Sure, the entire QSPI read operation is longer than this, but there’s never a time when we’ll need to output more valid bits than this. Indeed, after these bits get sent, the controller will switch the I/O lines from output to input modes, so again there’s no reason to care about these bits after the output duration of this operation ends.

The last QSPI I/O interface item that needs to be controlled is the I/O mode, to be used in determining which bits are set to outputs and which bits to inputs in the external I/O controller.

We’ll start in NORMAL_SPI mode, and then transition on a bus request

to QUAD_WRITE mode in order to send the address of the data we wish to read.

initial o_qspi_mod = NORMAL_SPI;

always @(posedge i_clk)

if (i_reset)

o_qspi_mod <= NORMAL_SPI;

else if (bus_request)

o_qspi_mod <= QUAD_WRITE;Once we get past the address and mode bits, we can then go into QUAD_READ

mode to read our data.

else if ((ckstb)&&(clk_ctr <= 5'd9))

o_qspi_mod <= QUAD_READ;That’s the logic necessary to control a read.

But what about the rest of our bus logic? While all of this is going on, we need to be doing a couple of things. First, the bus must be stalled. Second, we need to be collecting data from the QSPI data lines to return to the bus. Finally, once the operation completes, we need to acknowledge the bus request, signaling that the data we’ve collected is now valid.

Let’s start with the stall signal. On any bus request, we’ll set the stall signal high since it will be many cycles before we can respond to another bus request.

initial o_wb_stall = 1'b1;

always @(posedge i_clk)

if (i_reset)

o_wb_stall <= 1'b1;

else if (bus_request)

o_wb_stall <= 1'b1;Then, at the end of every clock interval, we’ll adjust the stall signal so that

it remains high until our operation is done. Once clk_ctr == 0, we’ll both

(potentially) acknowledge the request, and drop our stall signal.

else if (ckstb)

begin

if (clk_ctr > 1)

o_wb_stall <= 1'b1;

else

o_wb_stall <= 1'b0;

endWe’ll come back to this in a bit and discuss how to handle the register delays

on our input wires, since that will force us to keep the o_wb_stall

line high even after our transaction has finished.

The Wishbone acknowledgement signal looks simple enough. Following the

clock cycle where clk_ctr==1, we’ll acknowledge this request.

always @(posedge i_clk)

if (i_reset)

o_wb_ack <= 1'b0;

else

o_wb_ack <= (ckstb)&&(clk_ctr == 1);Only … this is where we start to get in trouble with reality.

First, a formal proof

of this logic fails if the master drops the i_wb_cyc line before we have the

chance to set this acknowledgment. We can’t interrupt our

flash I/O cycle when this happens,

lest we fail to output the 0xa0 mode bits and the

flash chip get placed into a

state other than the XIP one. Therefore, we’ll need to keep track of

whether the bus master has dropped the i_wb_cyc line and then suppress any

acknowledgments if it had.

The pre_ack logic below keeps track of whether or not we are still

within the original

bus cycle.

always @(posedge i_clk)

if ((i_reset)||(!i_wb_cyc))

pre_ack <= 1'b0;

else if (bus_request)

pre_ack <= 1'b1;That way we can use it, within our calculation of the bus acknowledgment, to return a proper value.

initial o_wb_ack = 1'b0;

always @(posedge i_clk)

if (i_reset)

o_wb_ack <= 1'b0;

else if ((ckstb)&&(clk_ctr == 1))

o_wb_ack <= (i_wb_cyc)&&(pre_ack);This isn’t quite the last of our problems either. What if a user wants to write to our read-only memory? Such an operation is undefined, but we can’t allow the bus to stall waiting for the result of an unsupported operation. If I believed in bus errors, I might raise one here–and there are a lot of good reasons to do so. I chose instead to quietly acknowledge any write request without doing anything instead.

else if ((i_wb_stb)&&(!o_wb_stall)&&(!bus_request))

o_wb_ack <= 1'b1;

else

o_wb_ack <= 1'b0;Our last step is to set and return our data value to the WB bus

That one’s easy, right? Anytime there’s a value to be read, shift it into our data register.

always @(posedge i_clk)

if (read_sck)

o_wb_data <= { o_wb_data[27:0], i_qspi_dat };But, when is there data to be shifted in? Here, I use a separate signal,

read_sck, to capture this logic. While I could have used ckstb, and

certainly did initially, I had to adjust this approach later to make certain

that o_wb_data never changes unless we are mid-operation with clk_ctr > 0

If we are in OPT_ODDR mode, the mode where SCK can toggle at the system

clock speed, then anytime the output clock is active, we should be reading

into our shift register.

generate if (OPT_ODDR)

begin : SCK_ACTUAL

always @(*)

read_sck = o_qspi_sck;You can see the resulting waveform trace in Fig. 19 below.

|

This would be catastrophic, though, if we only wanted to shift the data in

on every other clock. Hence, if we are dividing the clock by two, then

we want to read on the last clock of every clock cycle. One clock before

then, o_qspi_sck will be low.

end else if (OPT_CLKDIV == 1)

begin : SCK_ONE

initial read_sck = 1'b0;

always @(posedge i_clk)

if (i_reset)

read_sck <= 1'b0;

else

read_sck <= (!o_qspi_sck)&&(clk_ctr > 0);This extra logic is shown in the last line of the trace shown below in Fig. 20.

|

Finally, if we are dividing by anything more than two, then we’ll register the

read_sck signal, and use the ckpre signal as our indication that we

need to sample on the next clock.

end else begin : SCK_ANY

initial read_sck = 1'b0;

always @(posedge i_clk)

if (i_reset)

read_sck <= 1'b0;

else

read_sck <= (o_qspi_sck)&&(ckpre)&&(clk_ctr > 0);

end endgenerateAgain, this is shown in Fig. 21 below. Notice how ckpre is true one clock

before read_sck, as required to make this work. Notice also how the

clock goes through its negative cycle first, leaving the SCK positive

edge mid-interval.

|

To verify that this logic works, I used one of those “poor man’s sequences” that I discussed earlier.

Why not use a regular SystemVerilog sequence? Well, I started out using the more traditional SVA sequences. However, ultimately it was the variable clock rate that made using SVA sequences impossible, and so I had to switch to the poor man’s sequence approach.

By a poor man’s sequence, I mean something like the following:

First, I define how long this operation will take in logical steps, not

clock steps. This

includes the first step, found only when OPT_ODDR is low, where the CS_n line

is low and SCK remains high, followed by the six clock intervals of

the address. This is then followed by a parameterizable number of dummy cycles,

and then our eight data read cycles. We can capture this total length with the

localparam, F_MEMDONE.

localparam F_MEMDONE = (OPT_ODDR ? 0:1) + 6 + NDUMMY + 8;We can then define a sequence vector of this many states, plus one more for the acknowledgment cycle, with the meaning that if any of the bits in this vector is a one, then we are in that state.

reg [F_MEMDONE:0] f_memread;The logic to control this sequence is actually fairly simple. On a reset, the sequence is cleared.

initial f_memread = 0;

always @(posedge i_clk)

if (i_reset)

f_memread <= 0;Otherwise, we advance the sequence at the end of every SCK clock period.

else begin

if (ckstb)

f_memread <= { f_memread[F_MEMDONE-1:0], 1'b0 };There’s one problem with only stepping the sequence at the end of every

SCK clock interval: what happens to the acknowledgment? o_wb_ack can only

be high for one clock cycle, not for as many cycles as there are in an

extended SCK clock interval. Therefore, we’ll need to clear the upper bit

if our clocking is extended at all.

else

f_memread[F_MEMDONE] <= 1'b0;The last step is to start the sequence. We’ll start it on any bus

request. Well, almost. For reasons we’ll get into later we’ll start this

only on a bus request where the CS_n line is idle (high).

if (bus_request && o_qspi_cs_n)

f_memread[0] <= 1'b1;

endFrom here, we’ll shift this left one step per every state transition. Fig. 35 below shows an example of this, but only after adding in several more features, so let’s work our way up to that point.

Now we can make assertions about what’s supposed to happen in each step.

For example, we want to make certain o_qspi_sck is high during any OPT_ODDR

read operation.

always @(posedge i_clk)

if ((OPT_ODDR)&&(|f_memread[F_MEMDONE-1:0]))

assert(o_qspi_sck);We might also wish to assert that we start out this sequence in QUAD_WRITE

mode, and end it in QUAD_READ mode. There’s a couple steps in the middle

where our I/O mode doesn’t matter, but otherwise this fully constraints our

I/O modes.

always @(posedge i_clk)

if (|f_memread[6+(OPT_ODDR ? 0:1):0])

assert(o_qspi_mod == QUAD_WRITE);

else if (|f_memread[(OPT_ODDR ? 0:1)+7 +: NDUMMY])

begin end

else if (|f_memread)

assert(o_qspi_mod == QUAD_READ);In a moment, we’ll need a copy of what was read from the i_qspi_dat set of

input pins in order to verify that we received the right values. So let’s

create a second copy of the incoming data for that check.

always @(posedge i_clk)

if (ckpos && o_qspi_mod == QUAD_READ)

f_past_data <= { f_past_data[28:0], i_qspi_dat[3:0] };

endNext, let’s examine those first six clocks. These are the ones where we need to be outputting the address we were given from the bus. The first step to this check is making sure we have a copy of the last requested address to check against.

always @(posedge i_clk)

if (bus_request)

begin

// Make sure all of the bits are set

fv_addr <= 0;

// Now set as many bits as we have address bits

fv_addr[AW-1:0] <= i_wb_addr;

endWe can now use this to compare against what we are presenting across the port.

For example, during our first time interval, we’ll want to output address

bits 21:18.

always @(posedge i_clk)

if (|f_memread[(OPT_ODDR ? 0:1) +: 7])

begin

// 6 nibbles of address, one nibble of mode

if (f_memread[(OPT_ODDR ? 0:1)])

assert(o_qspi_dat== fv_addr[21:18]);Don’t let the OPT_ODDR scare you in this expression. This just references

the extra clock cycle used in the slow clock mode before lowering the SCK

line. During that cycle, output data values are don’t cares, so we don’t

check them here. However, if we are running in the faster mode, then we

don’t take an extra cycle–hence the reason for checking whether or not

OPT_ODDR is set here or not.

Here are the rest of the checks for the rest of the address intervals.

if (f_memread[1+(OPT_ODDR ? 0:1)])

assert(o_qspi_dat== fv_addr[17:14]);

if (f_memread[2+(OPT_ODDR ? 0:1)])

assert(o_qspi_dat== fv_addr[13:10]);

if (f_memread[3+(OPT_ODDR ? 0:1)])

assert(o_qspi_dat== fv_addr[ 9: 6]);

if (f_memread[4+(OPT_ODDR ? 0:1)])

assert(o_qspi_dat== fv_addr[ 5: 2]);Don’t forget that, because we are addressing the flash with 32-bit word addresses, that the bottom two of twenty-four bits are necessarily zero.

if (f_memread[5+(OPT_ODDR ? 0:1)])

assert(o_qspi_dat=={ fv_addr[1:0],2'b00 });Or, likewise, if we want to stay in XIP mode (and we do), that we have to

output a 4'ha following the address.

if (f_memread[6+(OPT_ODDR ? 0:1)])

assert(o_qspi_dat == 4'ha);

endNow let’s turn our attention to the returned result.

In OPT_ODDR mode, we get a result every clock tick. In this case,

the $past() function is ideal for checking if we are returning the right

values.

always @(posedge i_clk)

if (OPT_ODDR)

begin

if (f_memread[F_MEMDONE])

begin

assert(o_wb_data[31:28] == $past(i_qspi_dat,8));

assert(o_wb_data[27:24] == $past(i_qspi_dat,7));

assert(o_wb_data[23:20] == $past(i_qspi_dat,6));

assert(o_wb_data[19:16] == $past(i_qspi_dat,5));

assert(o_wb_data[15:12] == $past(i_qspi_dat,4));

assert(o_wb_data[11: 8] == $past(i_qspi_dat,3));

assert(o_wb_data[ 7: 4] == $past(i_qspi_dat,2));

assert(o_wb_data[ 3: 0] == $past(i_qspi_dat,1));On the other hand, if we haven’t yet reached the end of the sequence, then both the stall signal should be high and the acknowledgment signal should be low.

end else if (|f_memread)

begin

assert(o_wb_stall);

assert(!o_wb_ack);

endIf we are running in a slower clock mode, then $past() won’t work for us.

Instead, we can use the copy we just made of the incoming data to prove

that we received the right value.

end else if (f_memread[F_MEMDONE])

assert((!o_wb_ack)||(o_wb_data == f_past_data[31:0]));The rest of this logic should match the logic above.

else if (|f_memread)

begin

assert(o_wb_stall);

assert(!o_wb_ack);

endWe also want to make certain that, on the very last clock tick, the counter has properly returned to zero.

always @(posedge i_clk)

if (f_memread[F_MEMDONE])

assert(clk_ctr == 0);We’ll use one final assertion to double check that f_memread only ever has

one value active at any given time.

generate for(k=0; k<F_MEMACK-1; k=k+1)

begin : ONEHOT_MEMREAD

always @(*)

if (f_memread[k])

assert((f_memread ^ (1<<k)) == 0);

end endgenerateFinally, just to get some assurance that this actually works, we’ll add a

cover() statement to check that, yes, we truly can perform this operation.

always @(posedge i_clk)

cover(o_wb_ack && f_memread[F_MEMACK]);We now have a basic, functioning, QSPI flash controller. Or do we? So far, I’ve only presented how to handle requests once we’ve already gotten into this special XIP mode. We’ll have to come back to the question of how to get into this mode in the first place still. Similarly, we haven’t discussed how to send or receive arbitrary commands yet, or how to handle I/O delays. Let’s push those topics off for a bit longer, and look at how to read a second word without needing to go through the address cycle again.

Reading another word

|

With the logic above, we can now read a word from our flash chip. We can do this at the system clock rate, or any arbitrary division of it. In this section, let’s instead focus on what it takes to read data from the flash using the pipelined features of the Wishbone bus.

While you might wish to call this a burst bus mode, unlike other burst modes that I’ve worked with (WB, AXI, etc), this one doesn’t carry a burst length parameter, burst size, or even address increment information. For this reason, I often call this a pipelined mode rather than a burst mode, even though there are some obvious similarities between the two. As a result, you’ll find I often describe these as “pipe” or “piped” requests.

Within my design, this pipelined mode is controlled by the OPT_PIPE parameter.

Further, unlike many bus burst

modes, these piped requests are controlled on a beat by beat basis in the

master. There’s no pre-announcement of the number of values to be read, such

as in the AXI master specification

or in the Wishbone burst modes from the B3

specification that I’ve

carefully chosen not to

implement. Instead, we’ll

need to determine on a beat by beat basis if the next read request continues the

burst, or if we need to raise o_qspi_cs_n and start over with a new

QSPI

transaction.

Here you can see the definition of the OPT_PIPE parameter controlling whether

or not we support this mode in the first place.

// OPT_PIPE makes it possible to string multiple requests together,

// with no intervening need to shutdown the QSPI connection and send a

// new address

parameter [0:0] OPT_PIPE = 1'b1;If this parameter is set, the controller will respond to requests for subsequent

addresses. Hence, if you request a read from address A, and then while the

controller is busy making that happen you request a second read from address

A+1 (i.e. one word, or 32-bits later), then the controller should recognize

and honor this request before closing up the interface.

Sadly, that means we’re going to need to go back over a lot of our logic above and adjust it to make these subsequent reads possible.

The first step, though, is a bit of complicated logic determining if a subsequent read is even pending that would extend our burst access in the first place.

generate if (OPT_PIPE)

begin : OPT_PIPE_BLOCK

reg r_pipe_req;

wire w_pipe_condition;

reg [(AW-1):0] next_addr;An important part of this check is to know if a bus request is pending for

the next address. The first step of that logic is to calculate what that

next address, or next_addr, will be. In particular, this address is defined

as one more than the last address accepted. Hence, anytime !o_wb_stall, we

can create a copy of the incoming address plus one. (Notice we dropped the

check for i_wb_stb again.) Following requests for this next_addr

will then be honored without closing the interface.

always @(posedge i_clk)

if (!o_wb_stall)

next_addr <= i_wb_addr + 1'b1;This will capture the next_addr from not only the beginning of our first

request, but will also update it at the beginning of any subsequent address

as well, since the logic above, based upon the !o_wb_stall signal alone,

doesn’t care which of the two it is responding to.

A pipe request requires several things that all need to be true.

First, this has to be part of the last transaction. Remember how we used

pre_ack to keep track of whether the last transaction was aborted?

Here, pre_ack must be true–indicating that the last request was never

aborted. Second, there must be an outstanding request, so i_wb_stb must

be true as well. The new request must also be a read request, so !i_wb_we.

Further, it must be a request while we are already busy, and so the CS_n pin

must be active so !o_qspi_cs_n. The clock counter must be greater than

zero, and the outstanding request must be for the next address.

assign w_pipe_condition = (i_wb_stb)&&(!i_wb_we)&&(pre_ack)

&&(!o_qspi_cs_n)

&&(|clk_ctr[2:0])

&&(next_addr == i_wb_addr);This all makes sure that we are not only receiving a next address read request, but also that we are getting that request while we are still reading from the last address.

Since that’s a lot of logic, we’ll register it to keep it from slowing down the rest of the core.

initial r_pipe_req = 1'b0;

always @(posedge i_clk)

if ((clk_ctr == 1)&&(ckstb))

r_pipe_req <= 1'b0;

else

r_pipe_req <= w_pipe_condition;

assign pipe_req = r_pipe_req;Of course, if we aren’t supporting burst reads, then this value needs to be kept at zero–so the synthesizer can optimize away any unused logic.

end else begin

assign pipe_req = 1'b0;

end endgenerateRegistering all this logic is going to change our timing diagram somewhat, as shown in Fig. 23 below.

|

Notice from the figure that the logic recognizing a pipelined request needs

to first notice the request when clk_ctr == 3. Then pipe_req gets set

one clock later, when clk_ctr == 2, and so the o_wb_stall line gets

dropped when clk_ctr == 1. This is all set up so that clk_ctr can then

jump back from clk_ctr==1 to clk_ctr == 8 to start the second read.

The formal tools,

however, discovered the error in this basic set up. If

I ever take more than one clock cycle per SCK, then it might be that

clk_ctr == 1 for multiple cycles before o_wb_stall needs to be lowered.

Thanks to the formal

tools,

I think I found all of the missing logic tests.

All that’s left then is to patch this into our prior logic. The biggest

changes will be to our counter, clk_ctr, and our stall signal, o_wb_stall.

Neither the o_qspi_cs_n logic nor the o_qspi_sck logic needs to change,

since both of these are already set appropriately on any bus request.

Let’s start by updating clk_ctr. Before, on a read request, we set the

clk_ctr to 14+NDUMMY+(!OPT_ODDR). Now, if pipe_req and bus_request are

true, we’ll need to set it to 8 just before the operation ends.

// We start out as before

initial clk_ctr = 0;

always @(posedge i_clk)

if (i_reset)

clk_ctr <= 0;

else if ((bus_request)&&(!pipe_req))

// Notice that this is only appropriate for

// regular bus reads, and so the check for

// !pipe_req

clk_ctr <= 5'd14 + NDUMMY + (OPT_ODDR ? 0:1);

else if (bus_request) // && pipe_req

// Otherwise, if this is a piped read, we'll

// reset the counter back to eight.

clk_ctr <= 5'd8;

else if ((ckstb)&&(|clk_ctr))

// The rest is as it was before

clk_ctr <= clk_ctr - 1'b1;At first, updating the stall signal is easy. We still raise the stall signal on a bus request, regardless of whether or not its a piped (burst) request.

initial o_wb_stall = 1'b1;

always @(posedge i_clk)

if (i_reset)

o_wb_stall <= 1'b1;

else if (bus_request)

o_wb_stall <= 1'b1;Where things start to get difficult is when determining when to drop the stall line in order to accept this transaction.

It turns out that there’s two separate pieces of logic required. First, if

we are in OPT_ODDR mode and hence running at the system clock, then we’ll

need to drop o_wb_stall when clk_ctr == 2 so that o_wb_stall will be low

when clk_ctr == 1 as shown in Fig. 23 above.

else if (ckstb || clk_ctr == 0)

begin

if (ckpre &&(i_wb_stb)&&(pipe_req)&&(clk_ctr == 5'd2))

o_wb_stall <= 1'b0;

else if (clk_ctr > 1)

o_wb_stall <= 1'b1;

else

o_wb_stall <= 1'b0;Remember, we can’t make a mistake here, and timing is critical. Once mistake,

where o_wb_stall is low for one too many clock cycles, and we might

accidentally accept an extra request that we have no intention of processing.

On the other hand, if we are running slower than our clock speed, then we’ll

need to drop the stall signal while clk_ctr == 1 as discussed above.

This needs to be done one clock before ckstb when all of our states change,

and so we use the ckpre signal for that purpose. Notice that, if OPT_ODDR

is true, ckstb in the above condition will always be true, so this next bit

of logic will get ignored.

end else if (ckpre && (i_wb_stb)&&(pipe_req)&&(clk_ctr == 5'd1))

o_wb_stall <= 1'b0;Again, if you get confused by this logic at all, refer back to Figs. 11 or 12 above.

Verifying the piped reads follows much of the same logic as the original memory read verification: we use a poor man’s sequence. This sequence is only ever nine steps in length, since all the variable length stuff was handled above. These eight states represent the eight new steps on the QSPI bus, as well as a final one to return an Wishbone acknowledgment.

localparam F_PIPEDONE = 8;

// ...

reg [F_PIPEDONE:0] f_piperead;Now we can define a shift register with eight states (plus one for the acknowledgment), and step through it every time a clock period completes. This should look very similar to the shift register associated with the poor man’s sequence for reading in the first place.

initial f_piperead = 0;

always @(posedge i_clk)

if ((i_reset)||(!OPT_PIPE))

f_piperead <= 0;

else if (ckstb) begin

// Shift left, to advance the states in our sequence

f_piperead <= { f_piperead[F_PIPEDONE-1:0], 1'b0 };

// Likewise, we start this sequence on a bus request when we

// are already running

f_piperead[0] <= (bus_request && !o_qspi_cs_n);Of course, if the states last longer than a single clock, then we’ll need to make certain that any bus acknowledgments still don’t last any longer than a single clock.

end else if (!OPT_ODDR)

f_piperead[F_PIPEDONE] <= 1'b0;Using this state sequence vector, we can now make assertions about this second part of our state machine. For example, on that last beat of the sequence, either the data is right, or the acknowledgments must be low–in which case we don’t care what’s in the data.

always @(posedge i_clk)

if (f_piperead[F_PIPEDONE])

assert((!o_wb_ack)||(o_wb_data == f_past_data));Now let’s look at the rest of the steps in the sequence. Prior to our

acknowledgment, we should be stalled until the end of the SCK clock cycle.

else if (|f_piperead)

begin

if (!ckstb)

assert(o_wb_stall);Once we hit the end of the SCK clock cycle, we should still be stalled for all

stages except the one before we are done. That one exception is the stage,

shown in Fig. 23 above when clk_ctr == 1, where we might possibly accept

another request.

else if (!f_piperead[F_PIPEDONE-1])

assert(o_wb_stall);Finally, unless we are acknowledging the last memory cycle, the acknowledgment line must also be low. (Remember, we checked for our own acknowledgment cycle earlier in this cascaded if statement.)

if (!f_memread[F_MEMDONE])

assert(!o_wb_ack);

endOne last assertion is necessary to tie our f_piperead vector to the clock

counter. On the very last cycle of f_piperead, the clk_ctr should be at

zero, unless we are extending into an additional burst read following this

one in which case clk_ctr should be eight.

always @(posedge i_clk)

if (f_piperead[F_PIPEDONE])

assert(clk_ctr == 0 || clk_ctr == F_PIPEDONE);For all other cycles, the clk_ctr should specify which of the f_piperead

bits is on.

else if (|f_piperead)

assert(f_piperead[F_PIPEDONE-clk_ctr]);As one final step to know that our core truly passes, we’ll add a cover statement to cover the acknowledgment from one of these pipe reads.

generate if (OPT_PIPE)

begin

always @(posedge i_clk)

cover(o_wb_ack && f_piperead[F_PIPEDONE]);

end endgenerateNow, when we run SymbiYosys in cover mode, we’ll get a trace that we can examine assuring us that our design truly did what we were expecting.

The Startup Sequence

|

Our core now possesses all of the functionality necessary to read from the flash, just not any of the functionality necessary to get into the Quad I/O XIP read mode that all of our reads will start from. Once there, we can read at full speed (or slower) upon any request, and we can continue that read request as long as the master continues issuing subsequent read requests. Getting into this mode in the first place will be the topic of this section. Well, that and how to patch the logic for such a startup sequence into the logic we’ve already written above.

Before getting into the details, I should note that I’ve built more than one of these startup scripts before. Sadly, they all end up being very device dependent, often because different Flash devices support different reset commands, and some need special instructions to set chip specific configuration registers. Hence, while the previous two sections are all (fairly) device independent, and while they all apply to any flash device that supports the Quad I/O XIP read mode, things become quite device dependent in this section.

When I built my first startup script,

I built my startup sequence from a giant counter. After letting the

flash idle for a period of time,

following the Spansion

specification I was following for starting the

flash, I would then toggle the CS_n

line as a form of a reset sequence, and then issue a single read command.

Sometimes this required setting the Quad-SPI enable bit in the configuration

register.

This all worked until I tried using the Micron

flash chip. In that case, toggling

the CS_n line without toggling SCK wasn’t guaranteed to do anything useful.

Worse, before setting the Quad-SPI enable bit, you had to set the write enable bit. And, if that wasn’t

all, the Micron

flash chip

required up to 10-cycles between the address and the

data. Not only that, but that number of cycles is clock rate dependent. If

you didn’t run at 100MHz, you might be able to use fewer dummy cycles–making

the number of dummy cycles not only vendor but also clock rate dependent. If

that wasn’t enough, my 100 MHz flash

implementation required setting the drive strength, measured in Ohms, in order

to actually get up to 100MHz, and that requires setting the write enable bit

again.

So I rebuilt my flash driver in order to support this Micron flash chip as well as the others.

Because of the number of times I’ve ended up rebuilding this startup script, I chose to rebuild it this last time using an array of startup micro-commands rather than a counter driven script. While this might not be as low logic as I like, it will at least be easy enough to adjust from one flash device to the next.

This, therefore, is the one piece of our “Universal” flash

controller

that remains device dependent–not counting the number of dummy cycles,

the FPGA

dependent number of wait states on registered I/O, the device dependent

SCK rate, or ….

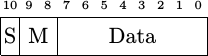

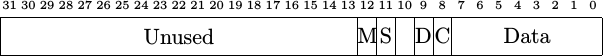

Here’s how our micro-control commands will be formatted.

|

-

We’ll use one bit to select between a command to be send to the device, and some number of counts to wait idle before the next command. I call this the wait bit,

M_WAITBIT, within the code and marked it asSfor sleep in Fig. 25 above. If this bit is set, the other 10-bits of the command word will indicate the number of counts to remain idle with theCS_nline inactive (high). If the bit is not set, theCS_nline will be made active (low). Indeed, this sleep mode is currently the only way to setCS_ninactive between commands. -

The next two bits, shown as

Mabove, will select the mode the command will be in, whetherNORMAL_SPI,QUAD_WRITE, orQUAD_READ. -

The final 8-bits will record an 8-bit data byte to be sent to the device–in either high or low speed, or ignored in

QUAD_READmode.

I’ll admit, this is even my second version of this micro-code interface. My first version was a basic bit-banging microcode interface. I switched to the more complicated command interface when the bit-banging one started to become difficult to maintain. Now, with all of the commands specifying 8-bit byte values, the command script has become much easier to read and check by eye.

The good news is that we will barely need to adjust anything else in our design to make this startup script work once it comes time to integrate it.

The startup script begins with the array of instructions, each 11-bits long.

localparam M_LGADDR=5;

//

reg [M_WAITBIT:0] m_cmd_word [0:(1<<M_LGADDR)-1];These words are set within a giant initial block. In general, this block needs to start by placing the flash chip into a known state from which we can send an SPI command to enter the QSPI XIP read state,

m_cmd_word[5'h08] = { 1'b0, NORMAL_SPI, 8'hff }; // Addr 1

m_cmd_word[5'h09] = { 1'b0, NORMAL_SPI, 8'hff }; // Addr 2

m_cmd_word[5'h0a] = { 1'b0, NORMAL_SPI, 8'hff }; // Addr 2

// Idle, to raise the CS_n line

m_cmd_word[5'h0b] = { 1'b1, 10'h3f };and end with a Quad Read I/O command, 0xeb,

24-bits of address (I set these to zero in general), a mode command, 0xa0,

some number of dummy cycles as determined by your specification sheet, and

then reading one or two bytes for good measure.

m_cmd_word[5'h14] = { 1'b0, NORMAL_SPI, 8'heb };

// Addr #1

m_cmd_word[5'h15] = { 1'b0, QUAD_WRITE, 8'h00 };

// Addr #2

m_cmd_word[5'h16] = { 1'b0, QUAD_WRITE, 8'h00 };

// Addr #3

m_cmd_word[5'h17] = { 1'b0, QUAD_WRITE, 8'h00 };

// Mode byte

m_cmd_word[5'h18] = { 1'b0, QUAD_WRITE, 8'ha0 };

// Dummy clocks, x10 for the MICRON flash

// This includes the 2 clocks for the mode byte above

m_cmd_word[5'h19] = { 1'b0, QUAD_WRITE, 8'h00 };

m_cmd_word[5'h1a] = { 1'b0, QUAD_WRITE, 8'h00 };

m_cmd_word[5'h1b] = { 1'b0, QUAD_WRITE, 8'h00 };

m_cmd_word[5'h1c] = { 1'b0, QUAD_READ, 8'h00 };

// Now read a byte for form

m_cmd_word[5'h1d] = { 1'b0, QUAD_READ, 8'h00 };

// Idle

m_cmd_word[5'h1e] = -1;

m_cmd_word[5'h1f] = -1;Some chips will also require you to set the Quad I/O bit in a configuration

register. That annoying Micron chip requires that

we first send a write enable, and then set the enhanced configuration

register, followed by sending the write enable again and the setting the

enhanced volatile configuration register before we can start our flash

command. In other words, check your

flash

chip vendor’s data sheet to see what information needs to be sent.

The startup interface within our controller centers and revolves first around

an internal signal I call maintenance, because in this maintenance (i.e.

startup) mode the design is offline for maintenance. Once the maintenance

flag clears, we’ll enter into our normal operations.

wire m_ce, new_word;

assign m_ce = (!m_midcount)&&(ckstb);

assign new_word = (m_ce && m_bitcount == 0);

initial maintenance = 1'b1;

initial m_cmd_index = M_FIRSTIDX;

always @(posedge i_clk)We both start out in maintenance mode, and we return to it upon any reset.

if (i_reset)

begin

m_cmd_index <= M_FIRSTIDX; // i.e. 0

maintenance <= 1'b1;Then, whenever it is time to move forward to the next word, we step forward

one index into our microcode array, m_cmd_index, stopping only when we get

to the last word in our sequence.

end else if (new_word)

begin

maintenance <= (maintenance)&&(!m_final);

if (!(&m_cmd_index))

m_cmd_index <= m_cmd_index + 1'b1;

endM_FIRSTIDX above is used to help speed us through

formal verification,

making it so the design skips the first several commands (mostly sleep

commands) and then goes directly into the startup sequence. That way, we can

get a cover() statement to generate a

trace showing us the whole

sequence.

always @(posedge i_clk)

if (f_past_valid)

cover($fell(maintenance));But I’m getting ahead of myself.

The m_final register above will be true when we get to the end of the

sequence. More on that in a moment as well.

Now that we have a command index into our micro-command table, we’ll want to use it to read from our array of startup commands.

initial m_this_word = -1;

always @(posedge i_clk)

if (new_word)

m_this_word <= m_cmd_word[m_cmd_index];We’re also going to need a flag to tell us when we are on the last command

word. We’ll call this m_final.

initial m_final = 1'b0;

always @(posedge i_clk)

if (i_reset)

m_final <= 1'b0;

else if (new_word)

m_final <= (m_final || (&m_cmd_index));Next, let’s implement our sleep or wait counter. This is the one that counts

down some number of sleep cycles, with o_qspi_cs_n held high (inactive).

Of course, the counter resets to its longest count, -1, on reset, and it

starts in the middle of a sleep cycle.

initial m_midcount = 1;

initial m_counter = -1;

always @(posedge i_clk)

if (i_reset)

begin

m_midcount <= 1'b1;

m_counter <= -1;Then, when it’s time to step to the next state, and time to move to the

next micro-command word, the counter starts up only if the M_WAITBIT (i.e.

the sleep bit) is set within the command word and the sleep count is greater

than zero.

end else if (new_word)

begin

m_midcount <= m_this_word[M_WAITBIT]

&& (|m_this_word[M_WAITBIT-1:0]);

if (m_this_word[M_WAITBIT])

m_counter <= m_this_word[M_WAITBIT-1:0];Once set, the timer counts down to zero. Likewise, the flag m_midcount

will reflect that we are waiting for the timer to complete.

end else begin

m_midcount <= (m_counter > 1);

if (m_counter > 0)

m_counter <= m_counter - 1'b1;

endOnce this m_midcount flag clears, we can then move to the next microcode

instruction. This is also why the logic above depends upon m_ce, which

itself is only true if !m_midcount: we only move forward to the next

instruction if our counter has reached zero.

What about the CS_n line and the mode bits? Let’s set them here, as well as

a m_bitcount to keep track of which bit within our eight that we are currently

transmitting.

initial m_cs_n = 1'b1;

initial m_mod = NORMAL_SPI;

initial m_bitcount = 0;

always @(posedge i_clk)

if (i_reset)

begin

m_cs_n <= 1'b1;

m_mod <= NORMAL_SPI;

m_bitcount <= 0;On every ckstb, we’ll move forward to the next step in our sequence.

end else if (ckstb)

begin

if (m_bitcount != 0)

m_bitcount <= m_bitcount - 1;Once every instruction has been acted upon, if this is the final instruction, then let’s cause these values to stop toggling.

else if ((m_ce)&&(m_final))

begin

m_cs_n <= 1'b1;

m_mod <= NORMAL_SPI;

m_bitcount <= 0;Otherwise if we are in the middle of a timer count, or if we are about to start

a timer count down, then again set the bits to idle. CS_n is deactivated,

and the port is placed in a NORMAL_SPI mode. The bit count is also left

at zero.

end else if ((m_midcount)||(m_this_word[M_WAITBIT]))

begin

m_cs_n <= 1'b1;

m_mod <= NORMAL_SPI;

m_bitcount <= 0;Finally, if we aren’t mid byte, and if this isn’t the last byte, and we

aren’t in a sleep cycle or about to start one, then we can accept

a new byte to transmit. CS_n is activated (lowered) automatically, and the

mode is drawn from the next two bits of the word. The bit count is set to

the number of remaining SCK clock periods necessary to send this word,

either 1 for a two-cycle word, or 7 for an eight cycle word.

end else begin

m_cs_n <= 1'b0;

m_mod <= m_this_word[9:8];

m_bitcount <= (!OPT_ODDR && m_cs_n)

? 4'h2 : 4'h1;

if (!m_this_word[9])

m_bitcount <= (!OPT_ODDR && m_cs_n)

? 4'h8 : 4'h7;

end

endWell, almost. If we aren’t running in OPT_ODDR mode, and we aren’t continuing

a previous command, then we’ll add in one extra clock cycle for SCK to be

high before dropping.

But what data should be sent? That comes from the rest of the bits in the

micro-command word, bits 7:0 as outlined in Fig. 25 above.

always @(posedge i_clk)

if (m_ce)

begin

if (m_bitcount == 0)

beginOn any new command to send data to the

flash chip, we’ll set the outgoing

data register, m_dat to the top four bits of the word for the QUAD* modes.

Otherwise, if we will be transmitting in NORMAL_SPI mode, then we’ll instead

set bit zero to the top bit, and the other three are don’t cares. m_byte is

then used to capture the remaining bits to be sent.

if (!OPT_ODDR && m_cs_n)

begin

m_dat <= {(3){m_this_word[7]}};

m_byte <= m_this_word[7:0];

end else begin

m_dat <= m_this_word[7:4];

m_byte <= m_this_word[3:0], 4'h0 };

if (!m_this_word[M_WAITBIT-1])

begin

// Slow speed

m_dat[0] <= m_this_word[7];

m_byte <= { m_this_word[6:0], 1'b0 };

end

endFinally, while we are within a word, we’ll want to shift the m_byte data

over by either one or four bits in order to grab the next bits to send.

end else begin

m_dat <= m_byte[7:4];

m_byte <= { m_byte[5:0], m_this_word[0] };

if (!m_mod[1])

begin

// Slow speed

m_dat[0] <= m_byte[6];

m_byte <= { m_byte[5:0], m_this_word[0] };

end

end

endThe last wire to set is the clock register, m_clk, that will be used to

drive the SCK pin. If we are in OPT_ODDR mode, where we are

running our clock at the system clock rate, this is as simple as setting the

clock to be identical to the negated CS_n pin.

if (OPT_ODDR)

begin

always @(*)

m_clk = !m_cs_n;

end else beginOtherwise, the m_clk pin will set the o_qspi_sck and hence the SCK wire

directly, so we’ll need to spend a bit more time at this. On a reset, the

SCK clock wire needs to idle at one. Otherwise, whenever m_clk is already

low, then the clock is raised on the ckpos signal. Further, in the middle

of a count down, the clock is kept idle (high). Otherwise, the clock goes

low if there’s another bit (nibble) to be sent.

always @(posedge i_clk)

if (i_reset)

m_clk <= 1'b1;

else if (m_cs_n)

m_clk <= 1'b1;

else if ((!m_clk)&&(ckpos))

m_clk <= 1'b1;

else if (new_word && m_this_word[M_WAITBIT])

m_clk <= 1'b1;

else if (ckneg)

m_clk <= 1'b0;

endThat’s the startup logic.

Since it doesn’t depend upon the inputs at all, it’s easily tested by a basic testbench. Alternatively, the one cover statement shown above will calculate a trace for us, showing what this startup routine does.

But how shall we integrate this within the rest of the design?

Actually, that’s the easy part, and part of the magic of using the

maintenance flag. First notice that there’s no feedback path from the

flash chip to this micro-code startup

design. That means that an extra clock cycle (or two) won’t affect our logic.

This makes it easy to adjust each of our basic controller output port logic

block to respond to the maintenance flag when it is set, and to ignore

the startup registers if not.

For example, in the case of o_qspi_cs_n, we’d have

initial o_qspi_cs_n = 1'b1;

always @(posedge i_clk)

if (i_reset)

o_qspi_cs_n <= 1'b1;

else if (maintenance)

o_qspi_cs_n <= m_cs_n;

else /// everything continues as before.In the case of o_qspi_sck, we’d have

initial o_qspi_sck = (!OPT_ODDR);

always @(posedge i_clk)

if (i_reset)

o_qspi_sck <= (!OPT_ODDR);

else if (maintenance)

o_qspi_sck <= m_clk;

else // everything continues as beforeThe same applies to o_qspi_mod, the bits used to control the external I/O

directions,

initial o_qspi_mod = NORMAL_SPI;

always @(posedge i_clk)

if (i_reset)

o_qspi_mod <= NORMAL_SPI;

else if (maintenance)

o_qspi_mod <= m_mod;

else // everything continues as beforethe Wishbone stall register,

initial o_wb_stall = 1'b1;

always @(posedge i_clk)

if (i_reset)

o_wb_stall <= 1'b1;

else if (maintenance)

o_wb_stall <= 1'b1;

else // everything continues as beforeand so forth and so on.

If we’ve done this all right, we can then get a cover trace showing that our startup script works using a simple,

always @(posedge i_clk)

cover($fell(maintenance));as I mentioned above.

Only, this doesn’t practically work.

The first problem is that I start the script with a very long set of delays.

These are required by some

flash chips. The problem with these

long delays is that the

formal tools

can’t practically work through that many cycles. So, to cut these delays

down, I introduced M_FIRSTIDX above–as a way to start the startup sequence

in the middle–but only during formal

verification.

The second problem was the delays within the control structure, and this is

a problem for the same reason as the long delays upon startup. To deal with

these, I arbitrarily kept the maximum number of counts to 3, but only during

FORMAL mode.

initial m_counter = -1;

always @(posedge i_clk)

if (i_reset)

begin

`ifdef FORMAL

m_counter <= 3;

`else

m_counter <= -1;

`endif

end else if (new_word)

begin

if (m_this_word[M_WAITBIT])

begin

m_counter <= m_this_word[M_WAITBIT-1:0];

`ifdef FORMAL

if (m_this_word[M_WAITBIT-1:0] > 3)

m_counter <= 3;

`endif

end

end else // continue as aboveMy third problem was that even with all this help, the startup design

still didn’t pass cover().

If you’ve ever had to debug a cover() failure, it can be quite annoying,

since the

formal tools

provide no information to you telling you why the

cover() request failed. Instead, all you learn is that the cover()

part of the proof failed.

The secret to solving problems like this with cover() is to break the

cover() problem up into smaller problems, to help you bisect and find the

problematic cycle.

While this was my approach, I may have also gone a bit overkill at it, as you’ll see below.

always @(posedge i_clk)

begin

cover(!maintenance);

cover(m_cmd_index == 5'h0a);

cover(m_cmd_index == 5'h0b);

cover(m_cmd_index == 5'h0c);

cover(m_cmd_index == 5'h0d);

cover(m_cmd_index == 5'h0e);

cover(m_cmd_index == 5'h0f);

cover(m_cmd_index == 5'h10);

cover(m_cmd_index == 5'h11);

cover(m_cmd_index == 5'h12);

cover(m_cmd_index == 5'h13);

cover(m_cmd_index == 5'h14);

cover(m_cmd_index == 5'h15);

cover(m_cmd_index == 5'h16);

cover(m_cmd_index == 5'h17);

cover(m_cmd_index == 5'h18);

cover(m_cmd_index == 5'h19);

cover(m_cmd_index == 5'h1a);

cover(m_cmd_index == 5'h1b);

cover(m_cmd_index == 5'h1c);

cover(m_cmd_index == 5'h1d);

cover(m_cmd_index == 5'h1e);

cover(m_cmd_index == 5'h1f);

endThis way, if cover(m_cmd_index == 5'h12) passed, but 5'h13 didn’t,

I could look at the number of steps between states and estimate how many

more steps the

formal tools

needed to reach the ultimate cover(!maintenance). When dividing the clock

by six, such that CLK_DIV == 5, this meant checking 560 states before the

proof would complete!

In the end, I also created some poor man’s sequences to describe the various possible micro-commands and make certain that each were properly carried out. We’ll skip these, since they basically follow the same form as the others above.

Arbitrary commands

The next step in implementing this core was to create an optional

configuration port through which arbitrary commands could be sent to

flash chip. Further, I chose to use

the parameter, OPT_CFG, to control whether this arbitrary command port should

be integrated into the

controller.

//

// OPT_CFG enables the configuration logic port, and hence the

// ability to erase and program the flash, as well as the ability

// to perform other commands such as read-manufacturer ID, adjust

// configuration registers, etc.

parameter [0:0] OPT_CFG = 1'b1;There are several reasons why we might want such a port. First, if we don’t implement any start up sequences, the arbitrary command capability can be used to create a startup sequence to place us into the XIP mode where the flash will respond to a sequence starting with an address instead of a command. Second, arbitrary command sequences are necessary for erasing and programming the flash, should you want that capability. Finally, while debugging the I/O, to see what is working and what is not, arbitrary commands are an absolute necessity to get a perspective of what is going on either right or wrong.

Of course, to do this, the flash controller will need to be able to place the flash chip into a state where it would no longer respond to read requests. This will necessitate that we add at least two more states to our basic state diagram, as shown in Fig. 26 below.

|